Measuring Automotive Bearing Clearances with Plastigauge

CLICK HERE to BUY PLASTIGAUGE TODAY

Application: Plastigauge is widely used in automotive maintenance to measure the clearance between a crankshaft journal and its plain bearing shells.

Step 1: Access the Bearings

- Remove the engine sump cover to expose the big-end bearings and retaining set screws.

- Clean away surplus oil around the area.

Step 2: Prepare the Bearing

- Unscrew the retaining set screws and release the bearing shells.

- Wipe the journal and bearing shell surface completely clean.

Apply:

- A thin smear of grease to the journal.

- A small amount of silicone release agent to the shell.

Step 3: Place Plastigauge

- Cut a piece of Plastigauge to the correct length (across the journal).

- Position it on the journal, using the grease to hold it in place.

Step 4: Reassemble and Tighten

- Refit the bearing shell.

- Tighten the retaining set screws to the manufacturer’s torque specification.

⚠️ Do not rotate the journal during this step.

Step 5: Measure the Clearance

- Remove the bearing shell again.

- The Plastigauge will now appear as a flattened stripe across the journal/bearing surface.

- Compare the width of the stripe with the calibrated gauge card supplied with Plastigauge.

- Read the corresponding bearing clearance value.

Step 6: Clean Up

- Ideally, remove all traces of Plastigauge with a clean oily cloth or an industrial degreasing solvent.

- Any residue left is oil soluble and generally harmless to lubricated metal surfaces.

✅ Tip: Proper clearance ensures correct lubrication and prevents bearing wear or seizure. Too much clearance reduces oil pressure, while too little clearance risks overheating and scuffing.

-

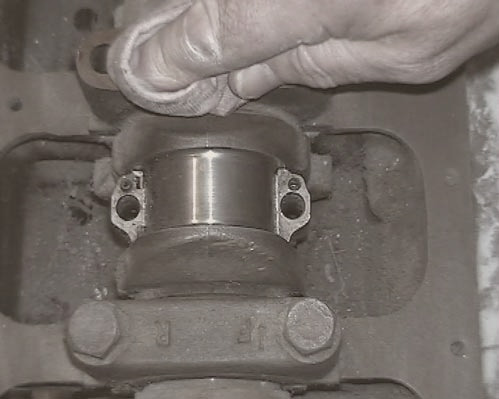

Fig. 1 It is recommended that surfaces be clean prior to use of Plastigauge -

Fig. 2 Plastigauge placed across the bearing surface -

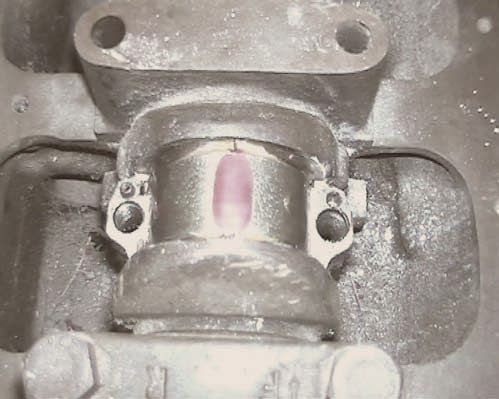

Fig. 3 Compressed Plastigauge ready for measurement. -

Fig. 4 De-formed Plastigauge compared with calibrated scale.